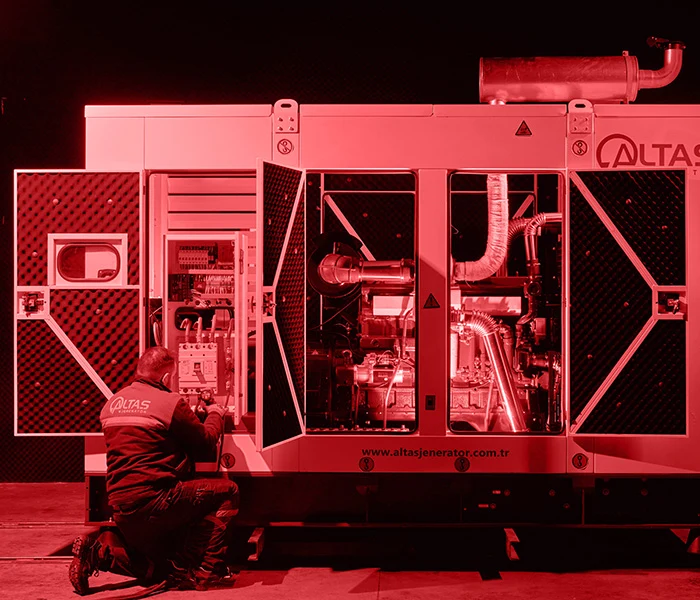

Initial Operation Initial Operation

The Power of Expertise

Having determined all your requirements, the correct power range and the ideal location, we quickly source your generator and install it in your facility. In order to ensure efficient operation of the generator, our authorized service technicians carry out the first run of the equipment.

Our customers are advised to avoid any operation by unauthorized people because they may cause the warranty to expire, not to mention that they may cause a drop in performance, which is guaranteed when initial operation of equipment is carried out by our authorized technicians.

After the initial run, we follow through with consultancy services when requested to ensure that your power is uninterrupted.

How to Start a Generator?

Generators are vital tools used to meet electricity needs. However, it is important to start and operate a generator correctly. Here are the steps to start and operate a generator:

Initial Checks: The first step is to perform the initial checks of your generator. These checks ensure that your generator operates safely and efficiently. During the initial check, inspect the fuel level, oil level and other important components of your generator.

Fuel System Preparation: Prepare the fuel system of your generator. Check the fuel tank and add fuel if necessary. Also, ensure that the fuel filter and fuel line are clean. Control Panel Preparation: Set your generator to the manual/test position through the control panel. Check the parameter settings on the control panel. Press the Start Button: Start the generator by pressing the start button. This will start the engine of the generator. Wait for the Engine to Run: After the engine starts, wait for it to run smoothly. Wait for a while to ensure that the engine is running well and at a stable speed. Applying Load: After starting your generator, if applicable, switch the output breaker to the ON position, manually perform the necessary transfer maneuvers if there is a transfer system, and gradually connect the loads. Make sure that the generator runs smoothly under load. Regular Checks and Maintenance: After starting your generator, regularly check and maintain it. Ensure that the oil level, fuel level, and other important components are periodically checked to enable your generator to operate safely and efficiently. Starting and running your generator is easy when following the correct procedures. However, it is important to carefully follow these steps for safety and performance. Additionally, regular maintenance and periodic checks of your generator ensure its longevity and reliable operation. There are situations where you may need to manually shut down the generator: When Required: When the electricity demand for which you are using your generator ends, you need to manually shut down the generator. Running your generator when there is no need for electricity can lead to fuel consumption and unnecessary wear. Therefore, it is important to shut down the generator when the electricity demand ends. Maintenance and Repair: When you need to perform maintenance or repair operations on your generator, you need to shut down the generator manually. By stopping the operation of the generator during maintenance or repair operations, you can ensure a safe working environment. Emergency Situations: In an emergency, you may need to quickly shut down the generator. For example, in case of a fire, gas leak or other emergencies, it is important to shut down the generator immediately. During emergencies, it is important to act quickly and effectively, regardless of the danger or risk that requires you to shut down the generator. Abnormal Operation: If you notice that your generator is running differently than usual or behaving unexpectedly, you may need to shut down the generator manually. For example, abnormal noises from the engine, vibrations or other signs may indicate a problem with your generator. In such cases, shutting down the generator immediately to prevent further damage is important. Manually shutting down the generator is vital for safety and performance. Properly shutting down the generator is a critical step to prevent unnecessary damage and provide a safe working environment. Therefore, when faced with the situations mentioned above or unexpected behaviors of your generator, it is important to shut down the generator manually immediately. You can follow the steps below to manually shut down a generator: Offloading: First, turn off or disconnect all loads connected to your generator. This prevents the generator from running idle and suddenly stopping under load. If applicable, switch the output breaker to the OFF position, manually perform the necessary transfer maneuvers if there is a transfer system, and ensure power supply from the grid. Running the Engine on Idle: Run the generator engine on idle to allow it to cool down slowly. By running the engine on idle, you can prevent overloading your generator and ensure the longevity of your engine. Stopping: Locate the stop button of your generator and press it. This will shut down the generator’s engine and stop the power generation. Cooling Process: After shutting down the generator engine, wait for it to cool down. Cooling the engine may take a few minutes, so keep the generator under control and take safety measures in the surrounding area during this time. Regular Maintenance: Before shutting down the generator, don’t forget to perform regular maintenance procedures. Check the oil level and add oil if necessary, clean the air filter, and protect your generator from external factors. When manually shutting down the generator, it is important to pay attention to safety precautions. While shutting down your generator, carefully look around to ensure the safety of the surroundings and take precautions against fuel or electrical leaks. Additionally, when shutting down your generator, carefully follow the manufacturers instructions and implement the specified procedures.Manual Shutdown of a Generator

How to Manually Shut Down a Generator?